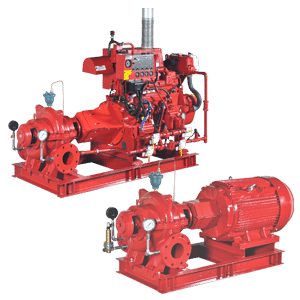

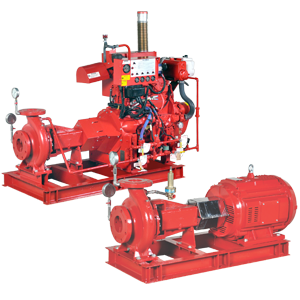

Fire Fighting Pumps Back pull-out - UL Listed NFPA 20 Design

Product Details:

Fire Fighting Pumps Back pull-out - UL Listed NFPA 20 Design Price And Quantity

- 1 Piece

Fire Fighting Pumps Back pull-out - UL Listed NFPA 20 Design Trade Information

- as per oder Per Week

- as per oder Week

Product Description

Fire Fighting Pumps Back pull-out - UL Listed NFPA 20 Design

FLBS fire pump-set offers all the features & benefits as mentioned in LBS standard pump series data booklet. Following are the additional features & benefits offered by these pump-sets:

Features

State-of-the-art design fire pumping system.

NFPA-20 design

Compact diesel engine driven pump package

Rugged construction

More economical than Horizontal Split Case diesel fire pump packages

Back pull-out design which simplifies inspection and maintenance without disturbing pipe work

The pump impellers are dynamically balanced to grade 6.3 of ISO 1940-1

Efficient operation

Lower initial cost

Reduced installation time and cost

Easy access to all working parts

Ease of maintenance

Single source unit responsibility.

Applications:

The FLBS fire pump-sets are used in small capacity, diesel engine or motor driven fire-fighting applications for supplying water to fire hose reels, fire hydrants or sprinkler systems in areas which are prone to the hazards of fire.

The typical applications are as follow:

Commercial complexes & Highrise buildings

Petrochemical industries and Gas plants

Airports and ports

Jetties

Marine applications

Power stations and transformer stations

Chemical industries

Manufacturing plants

Fire-work industries

Warehouses / Godowns

There fire pumps typically consist of the following equipment:

Single-Stage End-Suction pump

Electric motor or Diesel Engine

Cooling system for Diesel Engine

Fuel system for Diesel Engine

Battery for Diesel Engine electric start

Exhaust system for Diesel Engine

Diesel Engine / Electric Motor Fire pump controller

Suction and Discharge pressure gauges

Casing Relief Valve for Motor Fire pump

Base frame

All above equipment except fuel supply tank and fire pump controller are mounted on a common base frame.

We along with Lubi can also supply packaged fire pumping system with all required accessories ready for site installation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+