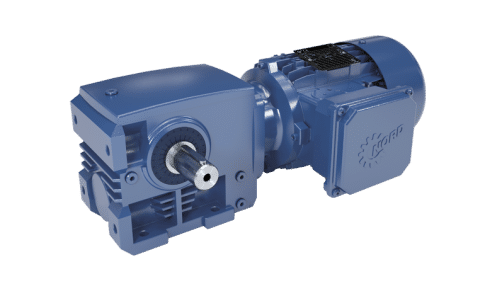

Universal Worm Geared Motor

Product Details:

- Gear Type Worm

- Material Cast Iron Body

- Processing Type Machined

- Gear Tooth Profile Worm

- Gearing Arrangement Worm

- Direction Reversible

- Output Torque 80 - 800 Nm

- Click to view more

Universal Worm Geared Motor Price And Quantity

- 1 , , Piece

- Class F

- 63 to 132 mm

- Natural Air Cooled

- S1 Continuous Duty

- -10C to +50C

- Foot / Flange / Universal Mount

- 50 Hz

- Low Noise Operation

- IP55

- Oil Splash Lubrication

- Three Phase

- IS/IEC Standards

Universal Worm Geared Motor Product Specifications

- 1440 rpm

- 80 - 800 Nm

- Cast Iron Body

- Reversible

- 415 V

- 14 rpm to 186 rpm

- Worm

- Machined

- Worm

- 75% - 85%

- 0.18 kW to 7.5 kW

- Worm

- Class F

- 63 to 132 mm

- Natural Air Cooled

- S1 Continuous Duty

- -10C to +50C

- Foot / Flange / Universal Mount

- 50 Hz

- Low Noise Operation

- IP55

- Oil Splash Lubrication

- Three Phase

- IS/IEC Standards

Universal Worm Geared Motor Trade Information

- as per order Per Week

- as per order Week

Product Description

Universal Worm Geared Motor

Performance: 0.12 - kW

Torque range: 21 - 427 Nm

Features:

| Sizes: 5 |

|

| Mounting position: Universal |

|

| Ratio: 5.00:1 3000.00:1

|

|

Nord UNIVERSAL SI worm gear units provide a high-power density and are extremely compact. They are characterised by having low-noise torque transmission. Thanks to their simple and effective structure they take up considerably less room than other types of gear units

Characteristics of Nord Helical Worm Geared Motor:

High overload capacity

Application-specific versions

Soft and quiet running

Aluminium housing version for low weight

Optional 10:1 helical input stage and compound worm assemblies

Modular, flexible and versatile application

nsd tupH version possible

Oversized output bearings for high load capacity

Applications:

Intralogistics

Material handling

Versions:

Hollow and solid shaft gear units

Push-on, flange and foot mounted versions

Angled gear units

Universal Worm Gear Box with IEC adapter.

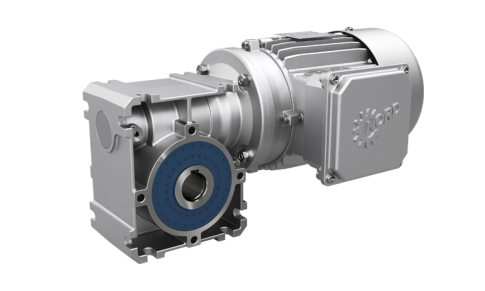

Universal Worm Geared Motor

Performance: 0.12 - kW

Torque range: 21 - 427 Nm

Features:

| Sizes: 5 |

|

| Mounting position: Universal |

|

| Ratio: 5.00:1 3000.00:1

|

|

Nord UNIVERSAL SI worm gear units provide a high-power density and are extremely compact. They are characterised by having low-noise torque transmission. Thanks to their simple and effective structure they take up considerably less room than other types of gear units

Characteristics of Nord Helical Worm Geared Motor:

High overload capacity

Application-specific versions

Soft and quiet running

Aluminium housing version for low weight

Optional 10:1 helical input stage and compound worm assemblies

Modular, flexible and versatile application

nsd tupH version possible

Oversized output bearings for high load capacity

Applications:

Intralogistics

Material handling

Versions:

Hollow and solid shaft gear units

Push-on, flange and foot mounted versions

Angled gear units

Universal Worm Gear Box with IEC adapter.

Versatile Mounting Options

Select from foot, flange, or universal mounting types, allowing the geared motor to accommodate varying installation requirements across industrial environments. This adaptability supports easier integration into existing and new machinery setups, enhancing operational efficiency and streamlining maintenance procedures.

Reliable and Efficient Operation

Designed for S1 continuous duty, this motor delivers sustained performance with an efficiency rating between 75% and 85%. Its oil splash lubrication system and natural air cooling method help maintain optimal temperatures and reduce wear, even in demanding applications, while its worm gear profile provides smooth and quiet operation.

Built for Industrial Standards

Compliant with IS/IEC standards, the motor is protected by an IP55 rating and boasts a rugged cast iron body. The design incorporates Class F insulation, ensuring safety and durability in ambient temperatures from -10C to +50C, making it suitable for diverse operating conditions in the Indian market.

FAQs of Universal Worm Geared Motor:

Q: How can the Universal Worm Geared Motor be installed in different applications?

A: This motor offers foot, flange, and universal mounting options, allowing for flexible installation across various industrial setups. You can choose the mounting type best suited to your equipment layout, ensuring compatibility and ease of integration.Q: What benefits does the S1 continuous duty cycle provide?

A: The S1 continuous duty cycle means the geared motor is engineered for uninterrupted operation over long periods, making it ideal for applications requiring round-the-clock reliability and consistent power output.Q: Where is the Universal Worm Geared Motor commonly used?

A: It is widely used in conveyors, processing machinery, material handling systems, and other industrial equipment. Its robust design and versatile mounting make it suitable for both indoor and outdoor installations within manufacturing, packaging, and warehousing industries.Q: What process ensures optimal cooling for the motor?

A: Cooling is achieved through natural air convection, which helps dissipate heat generated during continuous operation. This design supports a safe ambient temperature range of -10C to +50C without requiring external cooling devices.Q: How does oil splash lubrication contribute to motor performance?

A: Oil splash lubrication continuously coats the gears with oil, reducing friction and wear. This process enhances the longevity of the worm gears while maintaining operational efficiency and reliability.Q: What advantages does the IP55 protection class offer?

A: The IP55 protection class shields the motor from dust ingress and water jets, making it resilient against harsh industrial conditions and prolonging service life, especially in challenging environments.Q: When should traders or distributors consider sourcing this motor?

A: Traders and distributors should opt for this motor when seeking reliable, versatile, and standard-compliant solutions for their customers, particularly in sectors requiring efficient, low-noise, and high-torque transmission.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+